Ship Launching Airbags

Home » Marine Airbags » Ship Launching Airbags

High quality ship launching airbags manufacturer in China that you can trust. Competitive price and fast delivery.

- ISO 14409 certified

- Load capacity up to 100,000DWT

- Save more than 30% time and money

- Factory Direct

10+

Industry Experience

300 +

Project Complited

278 +

Happy Client

8+

Certificates

Ship Launching Airbags Form China

Ship launching airbag (also known as inflatable marine airbag, roller bag, air lift bag or salvage bag) is an innovative ship launching technology. It is made of high-quality synthetic rubber and high-strength cord material, providing higher load-bearing capacity and flexibility. It is not only used for conventional launching of ships, but also plays an important role in loading, floating and lifting of wrecks. In particular, it provides an efficient solution when salvaging stranded vessels.

This fender technology breaks through the limitations of traditional launching techniques (top-loading, side-loading and float-out) to provide a more flexible and efficient solution. It can help you save 30% to 50% of vessel launching cost, in addition, it can help you save more than 50% of time consumption.

Zhonghaihang’s launching airbags can be adapted to different vessel types and support the launching of vessels up to 100,000DWT. The airbags are designed and manufactured in accordance with ISO 14409:2011 standard.

Speak With Our Experts

Our technical team is ready to discuss your specific requirements and provide expert recommendations.

Ship launching airbag material

The reinforcing layer of the ship launching airbag consists of rubber-coated synthetic tire cord fabric. A unique “monolithic winding technology” is used to wind multiple layers of synthetic cord at an ideal angle. This technique ensures that the airbag distributes stresses evenly and maintains a stable internal pressure. We use 1400 dtex/2 or 1400 dtex/3 synthetic cord fabrics with a breaking strength of up to 310 N, which far exceeds the breaking strength of 205 N required by ISO 14409.

The outer rubber layer is designed to resist abrasion and is characterized by tear and stretch resistance, enabling it to cope with extreme environmental conditions. The inner rubber layer guarantees the sealing of the airbag, ensuring that the gas does not leak, further improving the reliability of the airbag.

rubber material performance

| Test Item | Value | Standard | Test Method |

| Tensile Strength (MPa) | ≥18 | ISO 37 | ISO 37 |

| Elongation at Break (%) | ≥400 | ISO 37 | ISO 37 |

| Hardness (Shore A °) | 60 ± 10 | ISO 7619-1 | ISO 7619-1 |

| Tear Strength (N/cm) | ≥400 | ISO 34-1 | ISO 34-1 |

| Compression Set (%) | ≤30 | ISO 815-1 | ISO 815-1 |

| Retained Elongation (%) | ≥80 | ISO 188 | ISO 188 |

| Elongation at Break Retained (%) | ≥80 | ISO 188 | ISO 188 |

| Hardness Change (Shore A °) | ≤8 | ISO 7619-1 | ISO 7619-1 |

| Static Ozone Aging (40℃ × 96h) | No Cracking | ISO 1431-1 | ISO 1431-1 |

Classification of Ship Launching Airbag

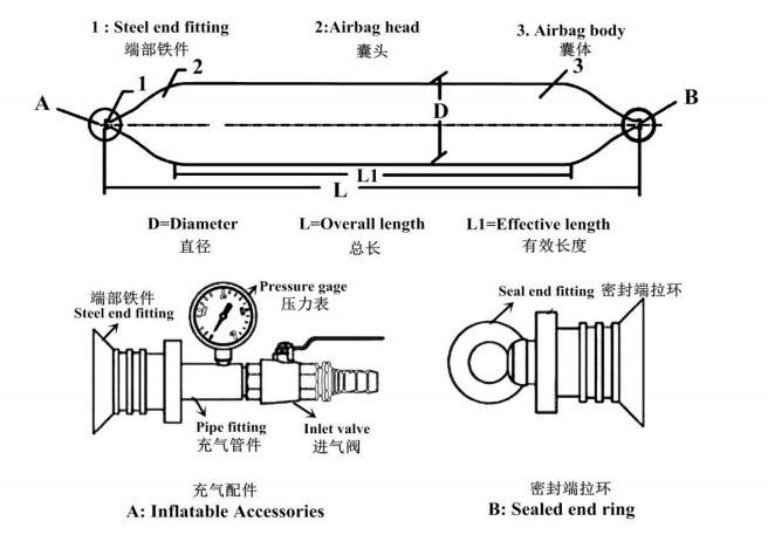

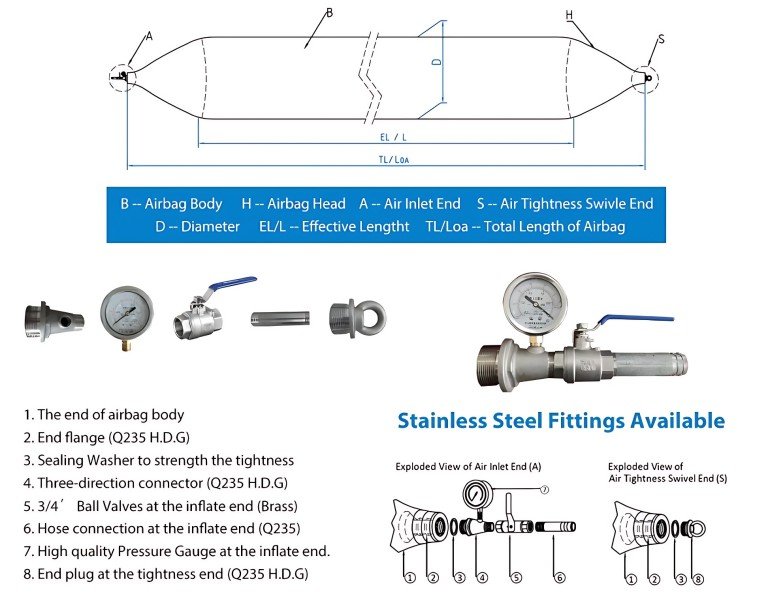

Our boat launching airbags feature an advanced cylindrical design with two strong tapered heads and tailports. The tail port design is a screw-in construction with a swivel ring and inlet kit. This configuration allows for a high degree of stability during inflation and deflation.

Structural design

The airbag is designed using high pressure resistant synthetic materials. The overall structure includes the airbag body, end fittings, and airbag inflation system. Each part is rigorously tested to ensure a high degree of safety and reliability.

Rubber airbag specifications

The standard specifications of rubber airbags can be flexibly customized according to project requirements. Common diameters range from 0.5 meters to 3 meters, and effective lengths from 1 meter to 32 meters, with a maximum of 35 meters. Load capacity can be selected as required, usually from 10 tons to 40 tons per meter. You can choose the right specification according to the demand. Special requirements can be customized to meet the unique requirements of the project by customizing the airbag parameters to specific conditions.

Diameter (D): 0.5~3m, or customized

Effective Length (EL): 1~32m, or customized

Total Length (TL): 1.2 ~ 35m, or customized

Loading capacity: 10 ~ 40 tons/m, or customized

Airbag Model: QP-ordinary type, QG-high load bearing type, QS-ultra-high load bearing type

End Connectors & Accessories

In order to ensure the good operation and safe use of rubber airbags. Our airbag end fittings and accessories are made of high quality materials and precision design. Mainly include:

Launch Airbag Types and Models

In order to respond to the needs of different types of boat launches, we offer you three highly effective types of boat launch airbags. We also offer customized options to meet a variety of needs and ensure that your ship launching mission is completed successfully.

QP (General Purpose): For medium loads, 3-5 layers of curtain design, widely used on most ships.

QG (High Load Type): With 6-8 layers of cord fabric, it is more suitable for heavy duty ship launching and provides strong load carrying capacity.

QS (Ultra High Load Type): Designed for extremely heavy loads, with 9 or more layers of cord fabric to ensure stable use even under the heaviest loads.

For example

QS9/2.0×20

QS9: 9 layers of fabric + 1 layer of rubber.

2.0: Diameter 2.0 meters

20: Effective length 20 meters

Keep your vessel safely and efficiently in the water with our airbags!

Applications

Ship launching: for all types of ships, especially large cargo ships and small merchant ships. Airbags provide a fast and safe method of launching.

Ship Towing and Moving: Especially in the absence of a drydock, airbags help to move the ship smoothly to the desired position.

Ship Salvage: During wreck salvage and rescue, airbags can provide support to help restore buoyancy to the vessel.

Pontoon support and underwater operation: Airbags can be used as pontoon support to help underwater operations such as wharf and pontoon construction and pipeline laying.

Rescue and Emergency Operations: In emergency situations, airbags can be used to right a sinking ship and provide fast and effective rescue operations.

Advantages

Economical: Airbags are more economical to use than traditional dry docking and techniques, reducing construction and transportation costs.

Flexibility: Airbags are lightweight, easy to transport and deploy, and can be adapted to different geographic and work environments.

Labor and Time Savings: Streamlines operational processes, improves operational efficiency and reduces labor costs.

Carrying capacity: able to adapt to different size and weight requirements from small to large vessels. A single airbag can carry up to 500TON of weight.

Reusable: Airbags have a service life of more than 6 years, reducing long-term costs and meeting environmental standards.

Our marine airbags Gallery

By choosing our boat launching airbags, you can ensure a smooth and safe launch every time! We offer a wide range of specifications according to different needs, customized for your boat.